SiLC Technologies LiDAR vision chip enters production at Cloud Light

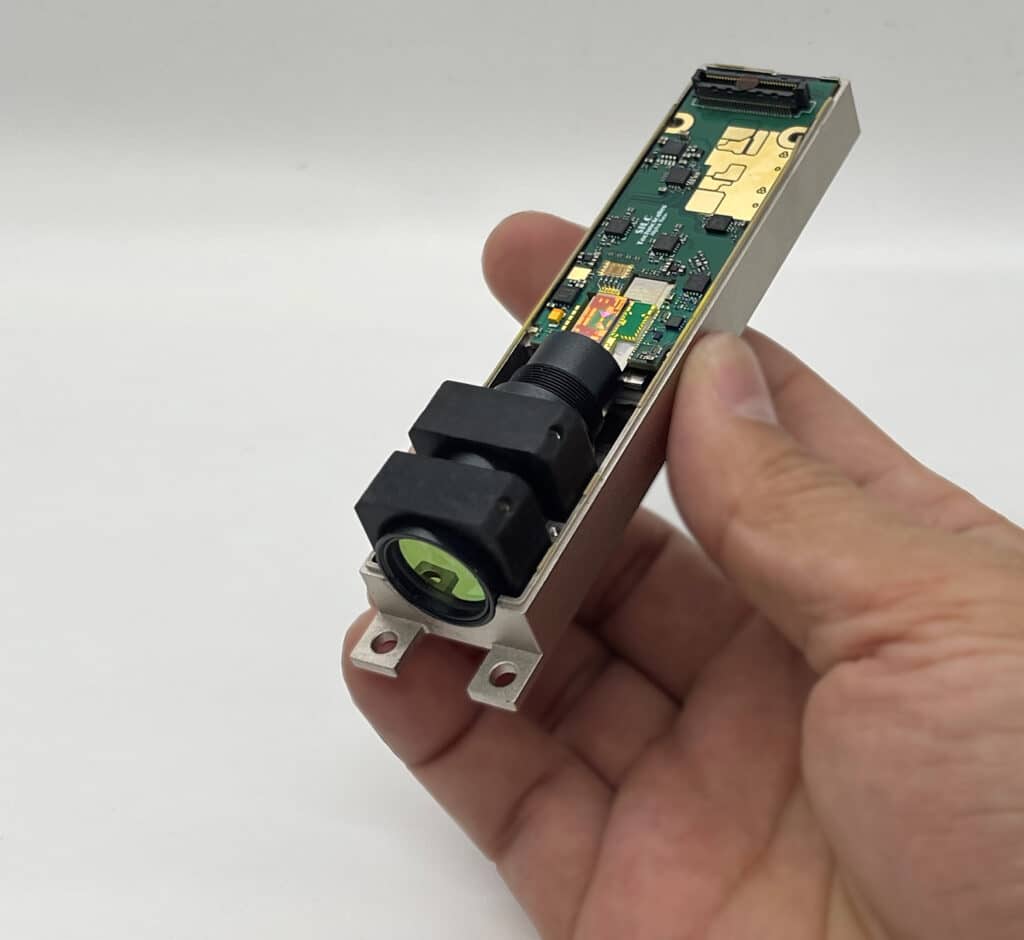

SiLC Technologies has announced a manufacturing partnership with Hong Kong-based Cloud Light for bulk production of SiLC’s Eyeonic Vision Sensor. SiLC has been developing a lower-cost chip that could ultimately help proliferate the use of computer vision systems used in factory automation, service robots, and drone delivery systems.

The manufacturing partnership will accelerate the production of Eyeonic Vision Sensor with all the shipments this year coming from the co-led semiconductor fabrication processes. Cloud Light has “proven capabilities” in optical module design, high volume precision assembly, testing, and reliability engineering to complement the SiLC manufacturing ecosystem. Some of the early production shipments are expected this year.

“To integrate all of the functionalities needed for a coherent LiDAR into a single photonic chip is a complex art that takes many years to master,” said Dr. Mehdi Asghari, SiLC’s CEO and founder. “The combination of precision optical assembly and automotive capabilities make Cloud Light an ideal partner for manufacturing our vision sensors. All modules that we ship to customers this year will be made by SiLC’s mature manufacturing ecosystem and led by Cloud Light.”

Last year, SiLC announced the commercial availability of chip-integrated frequency modulated continuous wave (FMCW) LiDAR technology, called the Eyeonic Vision Sensor. The Eyeonic Vision Sensor provides instantaneous depth, velocity, and dual-polarization intensity information while maintaining its immunity against multi-user and environmental interference.

“Cloud Light provides design capabilities and manufacturing excellence for advanced optical modules,” noted Dr. Dennis Tong, CEO and founder of Cloud Light. “Our automated assembly and test platform for silicon photonics enables SiLC to ramp up volume and scale its products to the automotive industry and beyond. We’re excited to work with the world’s leading 4D LiDAR chip supplier, together we offer a very unique value proposition to the market.”

SiLC uses frequency modulated continuous wave at the wavelength of 1550nm, which is broadly accepted as a standard to address eye safety regulatory concerns and enable volume deployment with minimum external interference. The sensor can be integrated into robotic vehicles and machines for them to be able to perceive environmental and external data for predicting future dynamics with low latency, low compute power, and rule-based algorithms.

“Our unique technology and innovative manufacturing process puts SiLC in the optimal position to provide the key building blocks needed for this next wave of significant innovation at a competitive price,” Asghari added.

Striim updates data streaming platform to help manage data pipelines

Grant program to disperse $2M for 5G projects in Indiana

Article Topics

chip | Cloud Light | computer vision | Lidar | manufacturing | SiLC Technologies

Comments